Customized auto spare parts,car parts,sophisticated parts from MIM

Production process

Mixing

Mix <20 µm typical powder with polymer (binder) system to produce the MIM feedstock. Theoretically speaking, the smaller the particle is, the bigger its specific surface will be, which is good for molding and sintering.

Granulation

The evenness of the mixture directly influences its fluidity and further influences the technical parameter of the injection molding, and the density and other performances of the final material.

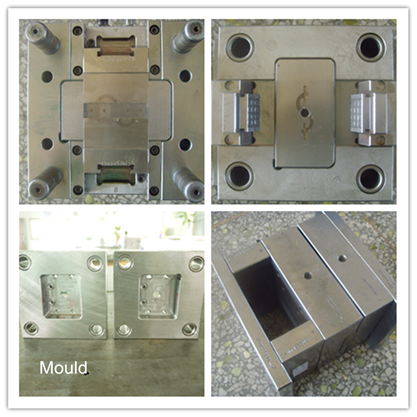

Molding Injection

Mold complex components from the feedstock using standard plastic injection molding equipment & techniques. During injection molding, the mixture is heated in the injection molding machine into plastic material with rheology, and then injected into the mold under certain pressure to mold a blank.

Sintering/Debinding

Remove the plastic binder by sintering parts in a high temperature H2/N2 pusher furnace. The high density of MIM component is achieved through high sintering temperature and long sintering time, which greatly improves the mechanical property of the component.

Secondary Operations

Parts can be machined, coined, heat treated, plated, and black-oxided and so on.

Material Customized

Considering the performance requirements on product strength, corrosion resistance, heat conductivity coefficient, density, hardness, etc., as well as the applications of the products, we will provide suggestions in the selection of materials and alloys. HZMIM provides various alloys, used for various industries such as automobiles, electronics, medical and tool accessories. When necessary, we can also create the customized alloys.

The injection molding materials include:

17-4PH (Sintered state) | 17-4PH (Heat treatment) | 316L | 310 N2-sintered | 310 Ar-sintered | 420 (Heat treatment) | 430 | 440 |

1110 | 4140 (Sintered state) | 4140 (Heat treatment) | 4605 (Sintered state) | 4605 (Heat treatment) | FN02-2% Nickel Steel | FN08-8% Nickel Steel |

430 | FeSi3 | FN50-50% 20Nickel Steel | Pure%20 Ir |

Comparison between Casting and other process:

Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

Density | 98% | 88% | 100% | 98% |

Tensile Strength | High | Low | High | High |

Elongation | High | Low | High | High |

Hardness | High | Low | High | High |

Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

Complexity | High | Low | High | Medium |

Surface Finish | High | Medium | High | Medium |

Production Volumes | High | High | Low | Medium |

Range of Materials | High | High | High | Medium-High |

Cost | Medium | Low | High | Medium |

Quality control

HZMIM's quality assurance and engineering organization apply statistical methods to production and final inspection to ensure that your parts meet defined critical specifications.

- All standard alloys plus application-specific materials developed upon request

- Experienced process and metallurgical team

- ISO 9001:2008 registered

- Historical control data saved electronically

- Production associated responsible for control plans