We can't spell SUCCESS without U.

We expect to make CUSTOMIZED hardware products for you.

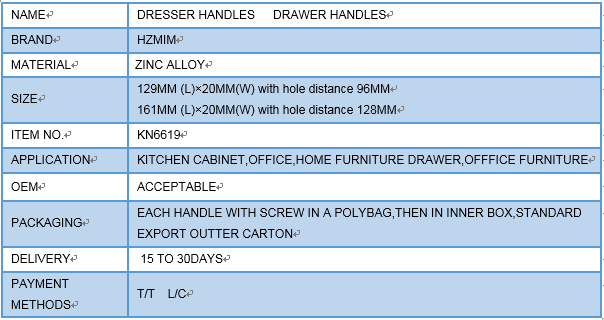

Product Details:

Brief Introduction of HZMIM:

Established in 2009, HZMIM specializes in the production of components through Metal Injection Molding technology. We are engaged in range of industries, like automotive, tool, electronics, medical treatment and consumer goods.

HZMIM is not only a MIM product manufacturer and we prefer to be your partner, you can rely on our MIM technology to realize your products ideas. We provide one-stop customized services from concept to market, including design, material, and molding, assembly, packing and shipping.

* Specializes in the mass production of precision metal parts through Metal Injection Molding.

*Over 35,000 square meters of productionworkshop, imported equipment (Cremer) and raw material (BASF)

* ISO9001:2008 and TS16949 certified, with an annual capacity of 50 tons of materials.

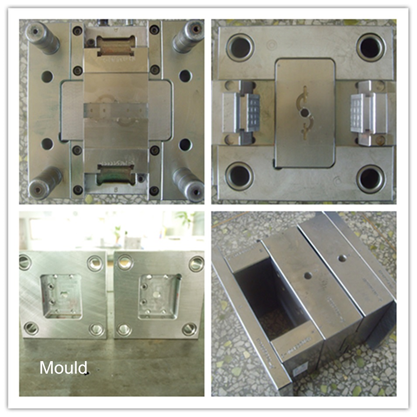

Design and Mold:

HZMIM provide mould design & manufacturing services depend on our years experiences. Also if you want to test your products, we provide custom prototypes and 3d print samples making services. You just need to send us your drawing, we’ll assist you to develop your project.

Manufacturing

Over 35,000 square meters of productionworkshop. Kinds of imported equipment like BASF deboning and sintering equipment, German Cremer continuous atmosphere and clearance type atmosphere sintering furnace. Also we have an ISO Class 8 (100,000) Clean Room.

Post Treatment:

If the product does not reach the desired effect, we can make the subsequent process for the product, and HZMIM provides the following services:

Machining | * full-automatic computerized numerical control (CNC) machining * electric discharge machining (EDM) * wire-electrode cutting, etc. |

Surface Finish | * Polishing (normal and mirror) * Brushing * Painting * Blasting * Laser engraving * Blackening * Carburizing |

Plating | * Catachresis * Electroplating (zinc, nickel, chromium, copper, etc) |

PVD | kinds of color, white, black, golden, brown, etc |

Heat Treatment | To meet the specific hardness requirement of your parts. |

Ultrasonic Cleaning | Clean the tight adhesion or embedded particles from the solid surface. |

Passivation | Ensure a part’s metallurgical stability by making its surface more passive and corrosion resistant. |

Quality Control:

HZMIM's quality assurance and engineering organization apply statistical methods to production and final inspection to ensure that your parts meet defined critical specifications.

* All import materials (BASF Germany) have the material reports and ROHS reports.

* Experienced process and metallurgical team

* ISO 9001:2008, TS16949 and FDA registered

* Kinds of test equipment

* HDBC report

Brief Introduction of Casting:

Casting is a manufacturing process by which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods.

Process of Investment Casting:

Comparison between Casting and other process:

Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

Density | 98% | 88% | 100% | 98% |

Tensile Strength | High | Low | High | High |

Elongation | High | Low | High | High |

Hardness | High | Low | High | High |

Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

Complexity | High | Low | High | Medium |

Surface Finish | High | Medium | High | Medium |

Production Volumes | High | High | Low | Medium |

Range of Materials | High | High | High | Medium-High |

Cost | Medium | Low | High | Medium |

We are always waiting here for your contacting!