Material | stainless steel,alloy,iron,brass |

Tolerances | <+ / -0.01mm |

The wall thickness | < +/- 0.017mm |

Multi-level parts | √ |

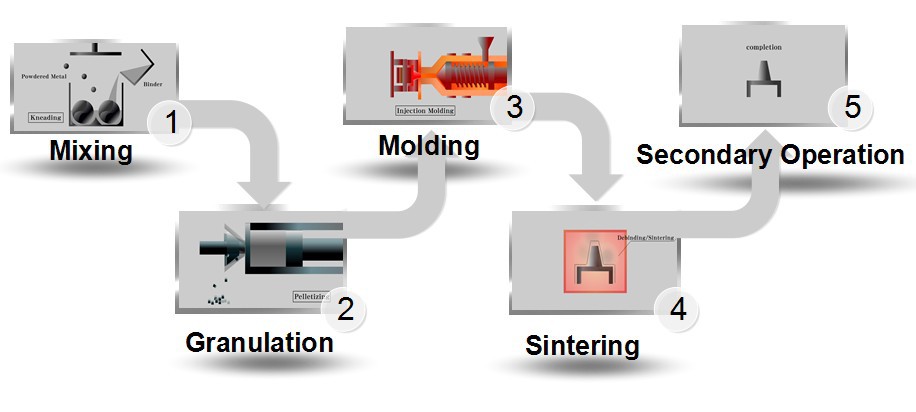

MIM Process | Mixing,Granulation,Molding,Sintering,Secondary operations |

Surface Treatment | Polishing,Anodizing,Black Oxide,Plating,Cataphoresis,magnetic abrasive finishing, etc |

QC System | 100% inspection before shipment |

MOQ | 100-500 PCS |

Price | Contact us for more Information |

Payment Terms | L/C, T/T,Paypal,Western Union |

Machining Capacity | 10000-20000 PCS per month |

Delivery Time | 15~30 days |

Main Markets | USA, UK, Western Europe, Australia,India etc. |

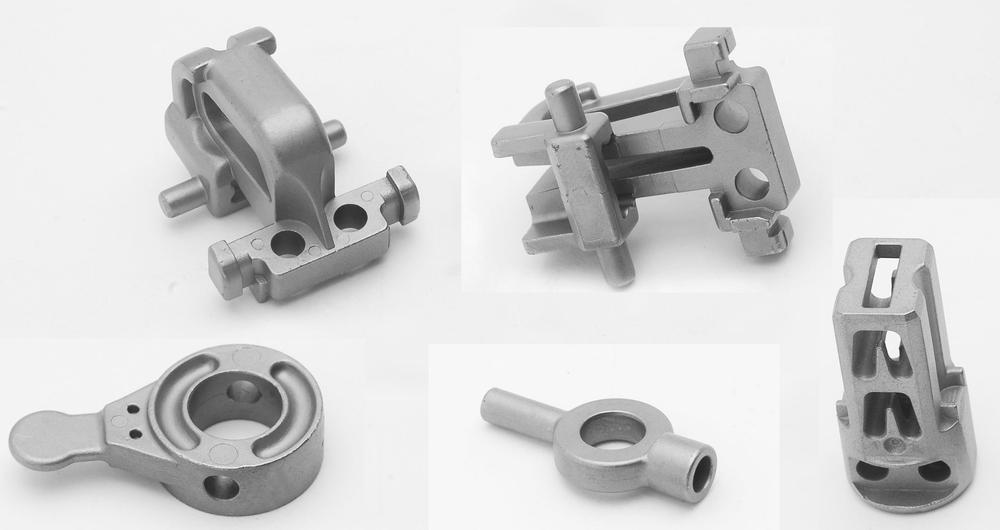

Application | Custom industrial parts for machine, auto,medical,hardware, etc |

MIM Process

l Mixing:mix <20 µm typical powder with polymer (binder) system to produce the MIM feedstock.

l Granulation:ground MIM feedstock into granules.

l Molding:the mixture is heated in the injection molding machine,and then injected into the mold under certain pressure.

l Sintering:Remove the plastic binder by sintering parts in a high temperature H2/N2 pusher furnace.

l Secondary operations:Custom parts can be machined, coined, heat treated, plated, and black-oxided and so on.

A quick way to custom high density parts

A economical way to save cost

A new way for your choice

Comparison between MIM with other Process

Parameter | MIM | COVENTIONAL PM | MACHINING | INVESTMENT CASTING |

Density | 98% | 88% | 100% | 98% |

Tensile Strength | High | Low | High | High |

Elongation | High | Low | High | High |

Hardness | High | Low | High | High |

Complexity | High | Low | High | Medium |

Surface Finish | High | Medium | High | Medium |

Production Volumes | High | High | Low | Medium |

Range of Materials | High | High | High | Medium-High |

Cost | Medium | Low | High | Medium |

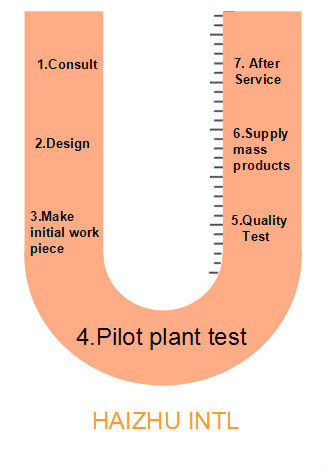

Value-added services

Machining | Fully-automated CNC machining centers and CNC electronical discharge machining(EDM). |

Heat Treatment | To meet the specific hardness requirement of your parts. |

Ultrasonic Cleaning | To thoroughly remove tightly adhered to embedded particles from solid surfaces. |

Passivation | Ensure a part's metallurgical stability by making its surface more passive and corrosion resistant. |

Surface Finishing | Many types of surface finishing services for your choice. |

Custom Products

HAIZHU INTERNATIONAL LTD was established on 2004, we are located in Hangzhou, the capital of Zhejiang Province. It is about 140km away from Shanghai Pudong international airport (PVG).

As the company grew, HAIZHU INTL showed its greatest strength:

• Advanced fabrication facilities & quality inspection equipment

• Perfect quality control system

• Rich development experience and manufacturing process

• Complete sales service network

• Custom parts

Experience :

l Over 95% of products are exported to Western Europe,USA

l More than 5 years experience in power tools industry

l We have served lots of famous company,such as Volkswagen,Tudor,Espon.

Quality Control

l ISO 9001:2000 registered

l Historical control data saved electronically

l Experienced process and metallurgical team

l Production associated responsible for control plans

l All standard alloys plus application-specific materials developed upon request

Instrumentation and Test equipment

l Torque Rheometer

l Precision Balances

l Impact Test Equipment

l LECO Carbon Analyzers

l Metallographic Equipment

l Mechanical Testing Equipment

l Density measurement equipment

l DCC Coordinate Measuring Machines

l Advanced In-process Gauging for Machining

l Advanced Surface Characteristic Instruments

l High Precision Length ,Parallelism,and Flatness Equipment